High quality confirmed by CE-standards certification

The products features by our company are broadly specialised equipment with advanced design and best specifications. They are characterised by high reliability Developed for years, they are reliable equipment for grain cleaning works. They make your work easier and quicker.

The three primary components that make graintec equipment unrivalled on the market:

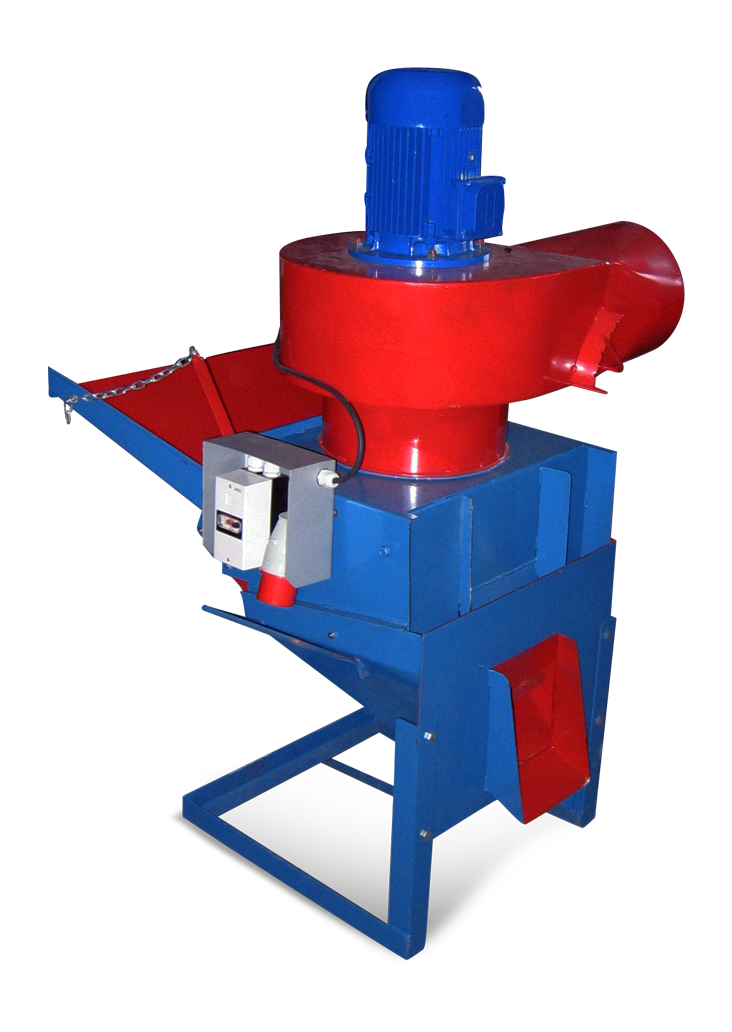

Machine operation:

The blower rotor driven by an electric motor draws air and pumps it into the transport pipeline.

The air flowing through the injection duct draws grain from the hopper and transports it to its destination through the pipeline.

Grain transport efficiency depends on the transport distance and height. It is adjusted by the gate in the hopper.

Application:

The conveyor is designed for the vertical transport of grain and other bulk materials (dry and light) used in agricultural production. The conveyor is particularly useful for grain handling works in agricultural grain warehouses. The conveyor is designed for continuous operation.

Transport up to the height of 7m without productivity losses |

Robust workmanship guarantees many years of failure-free operation |

Low power consumption (MAX. 7.5 KW) |

Grain blow-through in the silo |

Perfect for smaller farms |

Pneumatic transport dries grain and contributes to reduced mycotoxin growth |

Technical specifications

Motor power - 7.5 kW

Nominal voltage - ~400V, 3N-50Hz

The conveyor is designed to transport grain, vertically and diagonally.

Its operation consists in filling the hopper with grain, which is then suitably dispensed by the gate to reach the bucket spreader blades that rotate at an appropriate speed.

Through the rotary movement of the spreader, grain is projected above the upper edge of the outlet stub pipe, directly to the vertical transport duct pipe connected to it. The blower operates by pumping air into the injection duct, thus producing sufficient vacuum at the stub pipe outlet and in transport pipes to cause efficient suction of the grain projected vertically. With the vacuum produced in system pipes, the grain transported vertically has no direct contact with the side walls of pipes, which reduces friction, increases productivity and operation efficiency.

very high productivity, max. 30 t/h |

spreader-only operation in low transport |

application of blade spreader |

very low power consumption in relation to productivity |

vertical transport, up to 12 metres without productivity losses |

horizontal transport, up to 15 metres without productivity losses |

Loading to attics and floors |

Loading to any grain and feed silos |

Loading onto lorries |

|

Technical specifications

Electric motor - 4 kW, 2910 RPM

Electric motor - 5.5 kW, 900 RPM

Nominal voltage - ~ 400V, 3N-50Hz

The conveyor is designed to transport grain, vertically and diagonally. Its operation consists in filling the hopper with grain, which is then suitably dispensed by the gate to reach the bucket spreader blades that rotate at an appropriate speed. Through the rotary movement of the spreader, grain is projected above the upper edge of the outlet stub pipe, directly to the vertical transport duct pipe connected to it. The blower operates by pumping air into the injection duct, thus producing sufficient vacuum at the stub pipe outlet and in transport pipes to cause efficient suction of the grain projected vertically.

With the vacuum produced in system pipes, the grain transported vertically has no direct contact with the side walls of pipes, which reduces friction, increases productivity and operation efficiency.

Very high productivity, 40-60 t/h |

Spreader-only operation in low transport |

Application of blade spreader |

Very low power consumption in relation to productivity |

Vertical transport, up to 12 metres without productivity losses |

Horizontal transport, up to 15 metres without productivity losses |

Loading to attics and floors |

Loading to any grain and feed silos |

Loading onto lorries |

Versatile, light machine that could replace a bucket and screw conveyor |

Pneumatic transport dries grain and contributes to reduced mycotoxin growth |

Technical specifications

Electric motor - 11 kW, 1450 RPM

Electric motor - 7.5 kW, 2910 RPM

Nominal voltage - ~ 400V, 3N-50Hz

The operating principle of the PC 10 cleaning machine according to the invention is that during grain transport, the air generated by the fan motor is drawn through lower openings fitted with screens, which lifts and rotates grain in screw conveyor operating spaces and extracts contaminants lighter than grain. The flow of air through the air separator cleans the grain, but the rotary movement of grain in the screw conveyor space chambers also reduces the friction that occurs typically during grain movement in the screw conveyor. The control of the adjustment gate generates an air draft that enables cleaning without sorting grain or by using suitable screens for sorting grain into thick and fine.

The PC 10 cleaning machine is designed to transport grain, while cleaning it. This invention can be used primarily for transporting and cleaning the grain stored in silos and flat warehouses.

One of the essential advantages of the PC 10 cleaning machine is its capability to separate whole grains from contaminants, like: grain halves, husks, weed grains etc. Hence, during harvester threshing, screens can be set so that all contaminants are removed to the trailer and later on, during grain cleaning with our machine, best grains are separated from the rest. This provides a double benefit: weed grains are removed from the field, which becomes more weed-free every year, and after re-cleaning grain halves can be separated from other contaminants and used for animal feed.

It is also worth noting that a relative humidity of 70% in air and above 15% in plant raw material contributes to mycotoxin growth. Mycotoxins are relatively common in our environment, having a harmful impact on all living organisms, plants, animals and humans. The mycotoxin contamination of feeds is a known global problem. The grain collected by the harvester usually has more than 14% water content, a temperature higher than 17°C and significant contamination. This is an optimum environment for the growth of moulds that produce mycotoxins. Therefore grain producers are recommended to clean excessively contaminated grain.

productivity up to 15 t/h |

replaceable screens for screening different grains |

safer storage of grain without husks, dusts and worms that contribute to mycotoxin growth |

grain cooling by up to 4℃ per cycle |

Technical specifications

Electrical energy requirement

Fan drive electric motor - 3 kW, 2980 RPM

Screw drive electric motor - 3 kW, 1400 RPM

Nominal voltage - 3~ 400V/50Hz

Screens

Eye screens - 2-6 mm

Longitudinal screens - 20x4mm, 20x5mm

The operating principle of the PC 10 cleaning machine according to the invention is that during grain transport, the air generated by the fan motor is drawn through lower openings fitted with screens, which lifts and rotates grain in screw conveyor operating spaces and extracts contaminants lighter than grain. The flow of air through the air separator cleans the grain, but the rotary movement of grain in the screw conveyor space chambers also reduces the friction that occurs typically during grain movement in the screw conveyor. The control of the adjustment gate generates an air draft that enables cleaning without sorting grain or by using suitable screens for sorting grain into thick and fine.

The PC 10 cleaning machine is designed to transport grain, while cleaning it. This invention can be used primarily for transporting and cleaning the grain stored in silos and flat warehouses.

The operating principle of the PC 10 cleaning machine according to the invention is that during grain transport, the air generated by the fan motor is drawn through lower openings fitted with screens, which lifts and rotates grain in screw conveyor operating spaces and extracts contaminants lighter than grain. The flow of air through the air separator cleans the grain, but the rotary movement of grain in the screw conveyor space chambers also reduces the friction that occurs typically during grain movement in the screw conveyor. The control of the adjustment gate generates an air draft that enables cleaning without sorting grain or by using suitable screens for sorting grain into thick and fine.

The PC 10 cleaning machine is designed to transport grain, while cleaning it. This invention can be used primarily for transporting and cleaning the grain stored in silos and flat warehouses.

One of the essential advantages of the machine is its capability to separate whole grains from contaminants, like: grain halves, husks, weed grains etc. Hence, during harvester threshing, screens can be set so that all contaminants are removed to the trailer and later on, during grain cleaning with our machine, best grains are separated from the rest. This provides a double benefit: weed grains are removed from the field, which becomes more weed-free every year, and after re-cleaning grain halves can be separated from other contaminants and used for animal feed. It is also worth noting that a relative humidity of 70% in air and above 15% in plant raw material contributes to mycotoxin growth. Mycotoxins are relatively common in our environment, having a harmful impact on all living organisms, plants, animals and humans. The mycotoxin contamination of feeds is a known global problem. The grain collected by the harvester usually has more than 14% water content, a temperature higher than 17°C and significant contamination. This is an optimum environment for the growth of moulds that produce mycotoxins. Therefore grain producers are recommended to clean excessively contaminated grain.

productivity up to 15 t/h |

replaceable screens for screening different grains |

|

grain cooling by up to 4℃ per cycle |

option to attach a grain treatment machine |

Electrical energy requirement

Fan drive electric motor - 3 kW, 2980 RPM

Screw drive electric motor - 3 kW, 1400 RPM

Nominal voltage - 3~ 400V/50Hz

Screens

Eye screens - 2-6 mm

Longitudinal screens - 20x4mm, 20x5mm

From the grain outlet side, air suction has air inlets in counter-current to the transported grain, while from the inlet side, it has an air inlet directed under the screen. The main gate is the most important in the cleaning process. The smaller the opening between the gate and the hopper, the higher the cleaning force. An important role is also played by air draft adjustment placed on the fan, which enables reducing the air suction force for lighter grains. The cleaned grain outlet can be connected to various grain transport feeders and grain transporters, including the PPZ 30 or PPZ 60 pneumatic conveyor.

The machine enables cleaning grain from light contaminants, like dust or husks.

productivity 10-25 t/h |

can be connected to the PPZ 30 and PPZ 60 blower |

small weight, 90 kg |

Electricity demand

Fan-drive electric motor - 3 kW, 2905 rpm

Rated voltage 3~ 400 V/50Hz

Active grain ventilation consists in pumping large amounts of air through a grain layer. This process, under proper weather conditions, cools and dries the grain stored in a silo. The fan equipped with road wheels can be easily used to operate several silos.

Grain ventilation processes should be continued during the entire storage period. The blow-through air should have the lowest possible relative humidity. Such air provides a high capacity for removing dampness from grain.

The innovation of this machine consists in placing the “cyclone exhaust gas afterburner” above the combustion chamber.

The cyclone exhaust gas afterburner is a cylindrical chamber with circular central exhaust gas inlet in the bottom of the cylinder and a circular central outlet in the cylinder roof. Inside the afterburner, in the middle of its height, there is a circular steel deflector (the so-called glow plate) that maintains a high temperature in the afterburner and forces the flow of gas exhaust from the inlet towards the external cylindrical surface, where it meets the secondary air stream, which is introduced tangentially to the lateral cylindrical surface. The vortex stream of secondary air forces the same movement of hot exhaust gas, which contributes to good mixing of the input air and extends the residence time in the environment that strongly contributes to very efficient afterburning. The massive circular deflector is in addition equipped with steel rods, suspended under it and reaching the bottom of the cylinder, which improve the maintenance of high temperature throughout the exhaust gas mixture.

The air is fed to the “cyclone afterburner” by the airflow fan placed on the external cylindrical wall of the device wall.

The stream of air to the “cyclone afterburner” is set in service at specific load of the furnace working with the “afterburner”, so to maintain high performance and low emissions, the furnace must operate continuously with the power, for which the flow of secondary air is set, preferably close to nominal.

The exhaust gas flow from the “afterburner” to the four-draft horizontal exhaust gas-water exchanger.

The first draft duct and the front reversal chamber of the exchanger are equipped with heat sinks designed to maintain the exhaust gas temperature at the exchanger inlet and evenly distribute their stream on the water lamella surface. The front reversal chamber of the exchanger is closed with cleaning hatches that provide access for full maintenance of the exchanger, including the removal of vertical and horizontal heat sinks, removal of the partition wall and cleaning of the exchanger surfaces subject to heating.

Very high combustion efficiency by using the cyclone afterburner with glow plate |

Very low exhaust gas and dust emissions. As much as 10 times less than stated in the 5th emission class standard by using the buffer |

High boiler power at small sizes, 150 kW. Suitable for heating public utility buildings (schools, facilities etc.) |

High heat recovery by using a cassette heat exchanger with an innovative exhaust gas flow |

Up to 50% fuel economy |